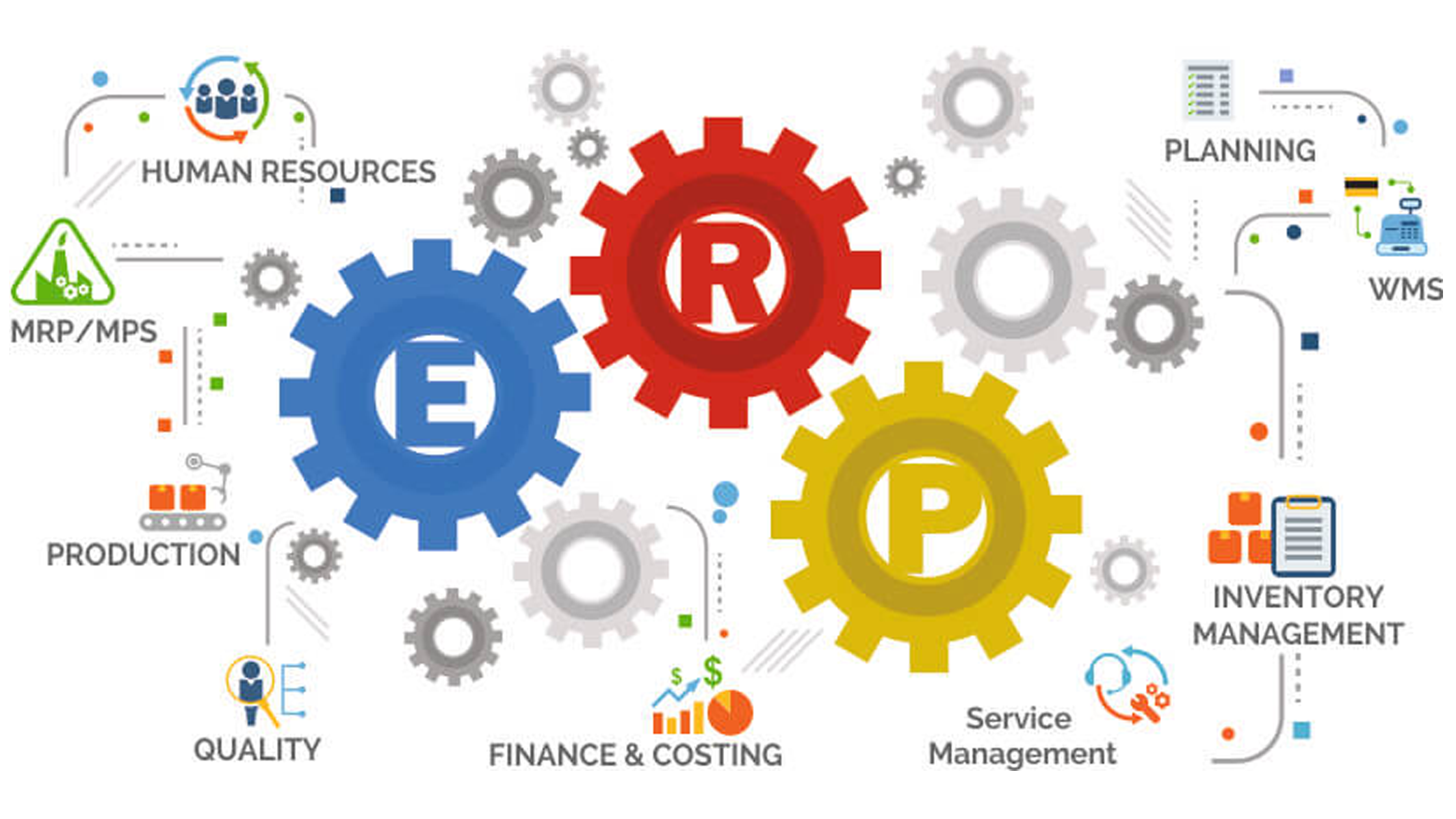

In the world of mechanical industries, precision, efficiency and timeliness are paramount. ERP solutions serve as the backbone, orchestrating seamless coordination between production, inventory, and distribution channels. By integrating processes, from procurement of raw materials to final product delivery, ERP ensures optimal resource utilization, streamlined workflows, and adherence to strict quality standards. With real-time insights and data-driven decision-making capabilities, mechanical industries can optimize production schedules, minimize downtime, and maintain competitiveness in a dynamic market landscape.

You can overcome your operational obstacles with the help of ERP.COM.BD. The software optimizes essential industrial manufacturing processes so that you and your team may focus more of your time on worthwhile tasks.

With the assistance of ERP.COM.BD's sophisticated business analysis tools, you can make informed decisions. By integrating various performance metrics and factors, our solution delivers you insightful reports.

Whether you want to create a new strategy or upgrade an existing one, ERP.COM.BD has got you covered. The software offers valuable insights that help you devise a winning manufacturing strategy thats help you a lot.

Mechanical industry have always been concerned about high overhead costs. ERP.COM.BD gives you detailed information on your company's spending that enabling you to look for ways to save unacceptable costs.

ERP.com.BD boosts scalability and customer satisfaction in mechanical industries. Our customized solutions optimize operations, ensuring seamless growth and enhanced client experiences.

Ensuring customer satisfaction is our utmost priority at ERP.com.BD. We are committed to providing personalized solutions that not only meet but exceed expectations, ensuring our clients' sustained success and lasting satisfaction.